Professional Sheetrock Repair Fort Worth for Quick Fixes

Professional Sheetrock Repair Fort Worth for Quick Fixes

Blog Article

Full Overview to Reliable and reliable Drywall Installment

Drywall setup is a critical element of any building and construction or restoration project, requiring a meticulous technique to ensure both effectiveness and dependability. It is vital to check out the nuances of each step in the procedure, as they collectively contribute to the total success of the drywall installation.

Crucial Tools for Drywalling

When getting started on a drywall installation job, having the right tools is critical for accomplishing a specialist finish. Necessary devices include a drywall blade, measuring tape, and a T-square, which are fundamental for accurate measurements and smooth cuts. A drywall lift is likewise highly valuable, especially for ceiling setups, permitting easier handling of hefty panels.

For attaching the drywall, a cordless drill and drywall screws are necessary. The drill ought to be outfitted with a drywall little bit to ensure effectiveness and accuracy. In addition, a key tool is the drywall saw, which helps with reducing around various other barriers and electric outlets.

Moreover, protective equipment such as shatterproof glass and a dust mask are vital to guarantee personal safety and security throughout the setup procedure. Making use of the right devices not only enhances the high quality of the installation however additionally simplifies the process, making the task extra reliable total.

Preparing the Space

Following, examine the condition of the ceilings and walls. Fix any existing damages, such as openings, cracks, or peeling off paint, to guarantee a smooth and also surface for drywall application. In addition, look for electric outlets, plumbing lines, and a/c ducts, marking their areas to avoid issues during installment.

It is also vital to measure the area properly, identifying the measurements of the walls and ceilings to compute the appropriate amount of drywall required. Create an in-depth strategy that includes the design and positioning of the drywall panels.

Installation Methods

Reliable installation methods are essential for achieving a professional surface in drywall projects. Appropriate dimension and cutting of drywall sheets are fundamental steps. Always determine the wall surface room accurately, enabling for any kind of outlets or switches. Utilize an utility blade for tidy cuts, racking up the paper face and snapping the board along the scored line.

When hanging drywall, begin with the top and work downward, guaranteeing that the long edge of the board is perpendicular to the framing. Secure the sheets with screws instead of nails, which provide greater holding power and lower the danger of standing out. Area screws every 12 inches along the sides and every 16 inches in the area of the board.

For corners, utilize corner beads to achieve sharp, clean sides. When mounting on ceilings, make use of a drywall lift or have a companion aid in holding the sheets in area (drywall installation). Preserve a gap of about 1/4 inch over the floor and ceiling to suit development and tightening

Completing Touches

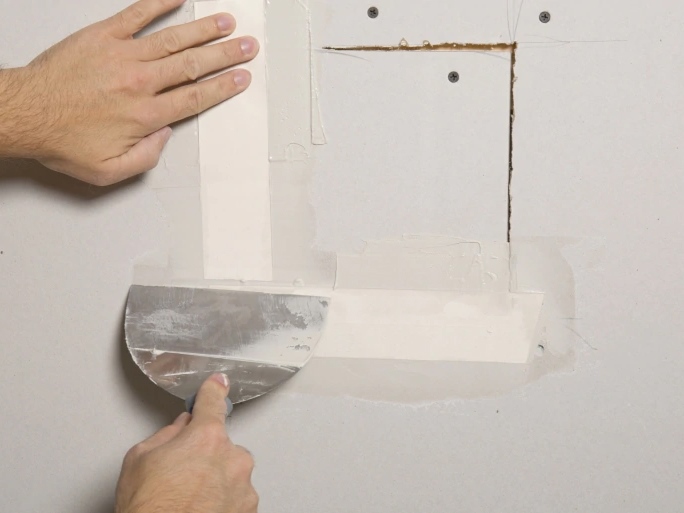

Begin by using joint tape over the seams. This can be either paper or fiberglass harmonize tape, with paper being liked for its sturdiness. Once the tape remains in location, it's time to use the very first coat of joint substance, also referred to as mud. Make use of a 10 to 12-inch taping knife to spread the substance evenly over the taped joints, feathering the edges to mix with read here the bordering drywall.

Enable the substance to dry extensively, usually 24 hr. After drying, sand the surface gently with fine-grit sandpaper to eliminate any kind of imperfections. drywall contractor. Repeat the mudding and sanding procedure, normally 2 to 3 layers, ensuring each layer is smooth and flush with the drywall surface

Typical Blunders to Avoid

Lots of Do it yourself fanatics run into pitfalls throughout drywall installment that can compromise the last outcomes. One common mistake is falling short to properly measure and cut drywall sheets.

Another frequent error is improper fastening. Making use of also couple of screws or nails can bring about loosened drywall, while overdriving fasteners can cause the paper to tear, compromising the structure. It's essential to maintain consistent spacing, typically every 16 inches, site and to guarantee that fasteners are flush with the surface area.

In addition, not resolving dampness problems before installation can result in mold development and architectural damage. Constantly assess the setting and usage moisture-resistant drywall in high-humidity areas.

Verdict

Trusted and reliable drywall installation requires thorough attention to detail throughout the process. Avoiding typical errors further contributes to a professional result, highlighting the value of accuracy and technique in successful drywall projects.

It is necessary to explore the nuances of each step in the procedure, as they jointly add to the overall success of the drywall setup.When embarking on a drywall installation project, having the right tools is important for accomplishing a specialist coating.For fastening the drywall, a cordless drill and drywall screws over here are required.Correctly preparing the area is necessary for an effective drywall setup.Efficient installment strategies are vital for achieving a professional finish in drywall projects.

Report this page